Johnson–Holmquist damage model

In solid mechanics, the Johnson–Holmquist damage model is used to model the mechanical behavior of damaged brittle materials, such as ceramics, rocks, and concrete, over a range of strain rates. Such materials usually have high compressive strength but low tensile strength and tend to exhibit progressive damage under load due to the growth of microcracks.

There are two variations of the Johnson-Holmquist model that are used to model the impact performance of ceramics under ballistically delivered loads [1]. These models were developed by Gordon R. Johnson and Timothy J. Holmquist in the 1990s with the aim of facilitating predictive numerical simulations of ballistic armor penetration. The first version of the model is called the 1992 Johnson-Holmquist 1 (JH-1) model[2]. This original version was developed to account for large deformations but did not take into consideration progressive damage with increasing deformation; though the multi-segment stress-strain curves in the model can be interpreted as incorporating damage implicitly. The second version, developed in 1994, incorporated a damage evolution rule and is called the Johnson-Holmquist 2 (JH-2) model[3] or, more accurately, the Johnson-Holmquist damage material model.

Contents |

Johnson-Holmquist 2 (JH-2) material model

The Johnson-Holmquist material model (JH-2), with damage, is useful when modeling brittle materials, such as ceramics, subjected to large pressures, shear strain and high strain rates. The model attempts to include the phenomena encountered when brittle materials are subjected to load and damage, and is one of the most widely used models when dealing with ballistic impact on ceramics. The model simulates the increase in strength shown by ceramics subjected to hydrostatic pressure as well as the reduction in strength shown by damaged ceramics. This is done by basing the model on two sets of curves that plot the yield stress against the pressure. The first set of curves accounts for the intact material, while the second one accounts for the failed material. Each curve set depends on the plastic strain and plastic strain rate. A damage variable D accounts for the level of fracture.

Intact elastic behavior

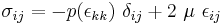

The JH-2 material assumes that the material is initially elastic and isotropic and can be described by a relation of the form (summation is implied over repeated indices)

where  is a stress measure,

is a stress measure,  is an equation of state for the pressure,

is an equation of state for the pressure,  is the Kronecker delta,

is the Kronecker delta,  is a strain measure that is energy conjugate to

is a strain measure that is energy conjugate to  , and

, and  is a shear modulus. The quantity

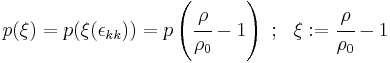

is a shear modulus. The quantity  is frequently replaced by the hydrostatic compression

is frequently replaced by the hydrostatic compression  so that the equation of state is expressed as

so that the equation of state is expressed as

where  is the current mass density ans

is the current mass density ans  is the initial mass density.

is the initial mass density.

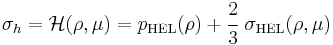

The stress at the Hugoniot elastic limit is assumed to be given by a relation of the form

where  is the pressure at the Hugoniot elastic limit and

is the pressure at the Hugoniot elastic limit and  is the stress at the Hugoniot elastic limit.

is the stress at the Hugoniot elastic limit.

Intact material strength

The uniaxial failure strength of the intact material is assumed to be given by an equation of the form

where  are material constants,

are material constants,  is the time,

is the time,  is the inelastic strain. The inelastic strain rate is usually normalized by a reference strain rate to remove the time dependence. The reference strain rate is generally 1/s.

is the inelastic strain. The inelastic strain rate is usually normalized by a reference strain rate to remove the time dependence. The reference strain rate is generally 1/s.

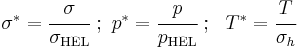

The quantities  and

and  are normalized stresses and

are normalized stresses and  is a normalized tensile strength, defined as

is a normalized tensile strength, defined as

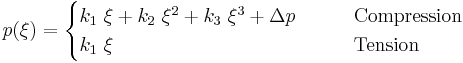

Stress at complete fracture

The uniaxial stress at complete fracture is assumed to be given by

where  are material constants.

are material constants.

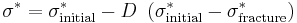

Current material strength

The uniaxial strength of the material at a given state of damage is then computed at a linear interpolation between the initial strength and the stress for complete failure, and is given by

The quantity  is a scalar variable that indicates damage accumulation.

is a scalar variable that indicates damage accumulation.

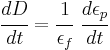

Damage evolution rule

The evolution of the damage variable  is given by

is given by

where the strain to failure  is assumed to be

is assumed to be

where  are material constants.

are material constants.

Material parameters for some ceramics

| material |  |

|

A | B | C | m | n |  |

|

|

Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg-m−3) | (GPa) | (GPa) | |||||||||

Boron carbide  |

2510 | 197 | 0.927 | 0.7 | 0.005 | 0.85 | 0.67 | 0.001 | 0.5 | 19 | [4] |

Silicon carbide  |

3163 | 183 | 0.96 | 0.35 | 0 | 1 | 0.65 | 0.48 | 0.48 | 14.6 | [4] |

Aluminum nitride  |

3226 | 127 | 0.85 | 0.31 | 0.013 | 0.21 | 0.29 | 0.02 | 1.85 | 9 | [4] |

Alumina  |

3700 | 90 | 0.93 | 0.31 | 0 | 0.6 | 0.6 | 0.005 | 1 | 2.8 | [4] |

| Silicafloat glass | 2530 | 30 | 0.93 | 0.088 | 0.003 | 0.35 | 0.77 | 0.053 | 0.85 | 6 | [4] |

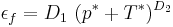

Johnson–Holmquist equation of state

The function  used in the Johnson–Holmquist material model is often called the Johnson–Holmquist equation of state and has the form

used in the Johnson–Holmquist material model is often called the Johnson–Holmquist equation of state and has the form

where  is an increment in the pressure and

is an increment in the pressure and  are material constants. The increment in pressure arises from the conversion of energy loss due to damage into internal energy. Frictional effects are neglected.

are material constants. The increment in pressure arises from the conversion of energy loss due to damage into internal energy. Frictional effects are neglected.

Implementation in LS-DYNA

The Johnson-Holmquist material model is implemented in LS-DYNA as * MAT_JOHNSON_HOLMQUIST_CERAMICS.[5]

References

- ^ Walker, James D. Turning Bullets into Baseballs, SwRI Technology Today, Spring 1998 http://www.swri.edu/3pubs/ttoday/spring98/bullet.htm

- ^ Johnson, G. R. and Holmquist, T. J., 1992, A computational constitutive model for brittle materials subjected to large strains, Shock-wave and High Strain-rate Phenomena in Materials, ed. M. A. Meyers, L. E. Murr and K. P. Staudhammer, Marcel Dekker Inc. , New York, pp. 1075-1081.

- ^ Johnson, G. R. and Holmquist, T. J., 1994, An improved computational constitutive model for brittle materials, High-Pressure Science and Technology, American Institute of Physics.

- ^ a b c d e Cronin, D. S., Bui, K., Kaufmann, C., 2003, Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA, in Proc. 4th European LS-DYNA User Conference (DYNAmore), Ulm, Germany. http://www.dynamore.de/dynalook/eldc4/material/implementation-and-validation-of-the-johnson

- ^ McIntosh, G., 1998, The Johnson-Holmquist ceramic model as used in ls-DYNA2D, Report # DREV-TM-9822:19981216029, Research and Development Branch, Department of National Defence, Canada, Valcartier, Quebec. http://www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA357607&Location=U2&doc=GetTRDoc.pdf

![\sigma^{*}_{\rm intact} = A~(p^* %2B T^*)^n~\left[1 %2B C~\ln\left(\cfrac{d\epsilon_p}{dt}\right)\right]](/2012-wikipedia_en_all_nopic_01_2012/I/92de0733e97dd1fcf8b8f25cde30c0a2.png)

![\sigma^{*}_{\rm fracture} = B~(p^*)^m~\left[1 %2B C~\ln\left(\cfrac{d\epsilon_p}{dt}\right)\right]](/2012-wikipedia_en_all_nopic_01_2012/I/dddcd8c150f899424513c97c38964bf4.png)